图文详情

产品属性

相关推荐

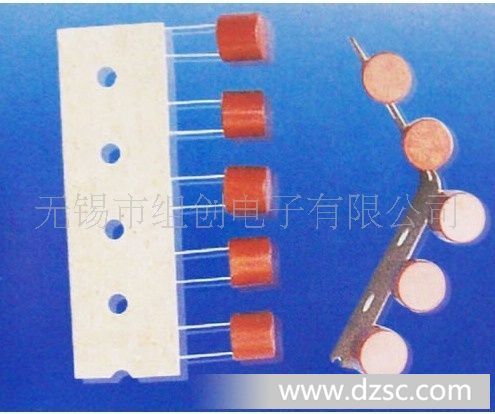

| 3.2 两端铜帽:须以导电率良好之黄铜底材料。 | |||||||||

| 3.2 Two br* end caps Made of br* of good conductiviry. | |||||||||

| 3.3 铜帽处理:铜帽部分镀镍 | |||||||||

| 标示*后若加"3"者,表示须镀镍。 | |||||||||

| 3.3 Coating of br* caps Plaring the surfacc with nickel If the indicarion is added with"s",it needs | |||||||||

| to be plard with silver. | |||||||||

| 3.4 铜盖强度:铜盖和玻璃本体间的扭力*小720g-cm. | |||||||||

| 3.4 Slrcmgth of br* caps The minimum tortion between br* caps and gl* tube is 720g-cm | |||||||||

| 4.电气特性: | |||||||||

| 4.Charactcristics of Electrical Appliancos | |||||||||

| 4.1 负载容量:额定电流测100%,能继续通电*熔化现象。 | |||||||||

| 4.1 Loading Capacity The Listed Electrical.(Included) add 100%for following,and it's available to let | |||||||||

| Current Kurrcnt Keep on flowinng without any melding | |||||||||

| 4.2 温度特性:进行上项测试1 小时,后继续维持原加之电流,每隔十分钟测试一次,继续测试 | Pict | ||||||||

| 三次,温度不得升高,若使用热偶式测量方法,(Thermometer method)则本体温度在70℃以下 | |||||||||

| 若使用温度计测量方法(Thermometer method)则在50℃以下。 | |||||||||

| 4.2 Temperature proceed: the prccedingtest for1 hours,keep testing iteith the original current | Pict | ||||||||

| every 10 minutes.Continue to test it for 3 times .The temperature is not allowed to be higher | |||||||||

| The main temperature is below 70℃by way of Thermocouple Method While it keeps below | |||||||||

| 50℃ by way of Thermometer Mcthod. | |||||||||

| 4.3 电阻测量:调整保险丝之额定电流值达10%时,在保险丝两端使用高阻*电压表测量降压值 | |||||||||

| 以计算电阻值或电桥方式测量(额定电流2 安培(含)以上者,无须测量电阻值) | Pict | ||||||||

| 4.3 Resistance Measuring:Adjust the fuse upto 10% more than listde electrical current the 10%,we | |||||||||

| mcasure on two ends of the fuse with high voltage meter,and caculare the resistance value with | |||||||||

| elec-trical brige way.(If the listed currecct equal or more the 2 Amp,it's not necessary to | Pict | ||||||||

| measure the resistance value.) | |||||||||

| CLEARING TIME | |||||||||

| 熔 断 时 限 | |||||||||

| 电流Ampere | 135% Rating | 200% Rating | 1000% Rating | ||||||

| 时间Time | >1H | <120S,>1S | >10mS | ||||||

| 电压Volfage | 250v | 250v | 250v | ||||||

| 5.机械特性Mechanical Properties:Terminal Conncctions&Lead Solderability | |||||||||

| 乃经下述三项* | |||||||||

| 5.1拉力强度Terminal Strength:当施加轴力向拉力 1.1 磅于两端导线(或套盖) 5 分钟后, | |||||||||

| 无松动或损坏现象发生。 | |||||||||

| 5.1Leads and/or caps are soldcred(adhcred)to withstand axial pulling force 1.1 pounds 5 | |||||||||

| min without loosening ou any harfulness to firmly arlachment | |||||||||

| 5.2 回转强试Torsion Strength: | |||||||||

| ① 固定一端铜头,另一端施加 720 g/cm的力左右摇动,铜头不得拉动及发生任何本体损坏 | |||||||||

| After being subjecteedd to 720 g/cm torsion go one cap while te othe terminal fixed,no any | |||||||||

| damage or loo*ning resulted | |||||||||

| ② 一端导线弯折90度,本体以原轴旋转360度(五秒),三次不同方向旋转。导线或结合处不 | |||||||||

| 发生损坏 | |||||||||

| One lead bent through90o,the body be clamped and rotated through 360o at a rate or 5 sec | |||||||||

| about the original axis,Vophisical damage to leads or connections twsulted after 3 successive | |||||||||

| -altematero-tations. | |||||||||

| 5.3 弯折强度Bending Strength:导线经过两次反方向之弯折后(弯折90度同折回原位谓之一次 | |||||||||

| 弯折)不发生损坏 | |||||||||

| After two bends of opposite ditections (bending through an angle of90oand back is detined as | |||||||||

| one bond)of lead,no damage are to be visualized. | |||||||||

10A-25A/125v250v大电流温度保险丝73度-240度通过UL CUL VDE PSE ROHS认证

保险丝座;SCI。R3-11。R3-12。R3-9。R3-13,PTF15。PTF45 PTF70。PTF50。PT35。PTF40。PTF55,PTF60。PTF30。R3-53。R3-49。R3-55,R3-52。R3-54,R3-28等各种保险座。

我们的产品广泛用于各种电子.电器.电源.充电器.汽车.等等各种电子产品

以*的生产技

术和ISO9001-2000质量管理体

系的*管理,公司生产的产品先后获得等产品*认证

,为了*合欧盟*质量要求,本公司依

据欧盟*质量要求生产出高质量*产品,产品远销东南亚、欧美、港、澳、台等世界各国和地区,

我们的成功来自于我公司的“科学管理,精心制作,顾客的需求,我们的追求”。

雄厚的资本,*的技术,开拓的精*,我公司将继续参与研制开发各类熔断体,欢迎社会各界有识

志士前来我公司指导、洽谈业务,共创美好未来

公司网址: www.wxfuse.com

电子:

贸易通: https://wxzucang.cn.alibaba.com

:

传真:

手机:

QQ:5

MSN:

是

组创

6*30

保险丝

电子

小型

*电压

尖头管状

F/快速

日规

无

125(V)

25(A)

10(A)

0(℃)

00(℃)